Engineering plastics gives producers the design flexibility they need to address complicated part requirements for cost-effectiveness and lightweight. Although high-quality plastic materials may be created fast and in large quantities, a comprehensive simulation is necessary to customize the materials to each product’s specific needs. Altair provides a full range of engineering plastic solutions to swiftly and reliably build unique plastic parts. Digitalization for Climate Protection and Sustainability Investments in digitization is necessary for success, and the plastics industry needs powerful tools for the early stages of development and beyond. Altair assists companies in enhancing the plastics value chain and achieving the industry’s sustainability and climate protection goals by supporting its extensive, potent technology portfolio. Additionally, it helps organizations in the ways listed below: replacement materials, Increased use of recycled materials, Analyse, and lessening your carbon footprint.

Improve Plastic Components

Even the most excellent material cannot compensate for performance losses caused by a part with the incorrect shape, even though simulation is frequently used to validate the performance of a mature component. Modern materials perform best when used in conjunction with an ideal geometric layout resulting from designs that are made to withstand the stresses and strains encountered during use. With topology optimization, the best material arrangement and load routes are identified to create optimal components. Shape optimization can be utilized for dimensioning in later stages of development, considering local material effects and enabling further evolution of the component design.

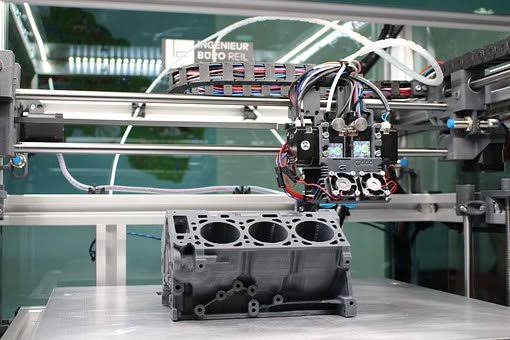

Development Of Plastic with Modern Techniques

Companies must consider the production method, part geometry, and material while developing thermoplastic components. Plastics reinforced with short glass or carbon fibers have anisotropic characteristics depending on how the fibers align during injection moulding. Modern optimization techniques aid in designing and developing parts through realistic numerical material descriptions. This enables us to consider the specific properties of plastic in the simulation.

Balance manufacturing and performance of Plastic Moulding

A greater understanding of how changing manufacturing process parameters may impact component material behavior is provided by simulation. As part of the design process, modern Plastic Injection moulding provides product quality control to guarantee part manufacturability. While analyzing and modifying part designs, engineers can optimize for form, fit, and function. Users of Altair’s manufacturing simulation tools can examine single- and multi-cavity family mould layouts. They can also feed system designs and mould and feed system designs. Additionally, they can enhance the runner, gate, and sprue positions to modify fiber orientations and prevent weakening weld lines.

The ultimate product, variations, and final properties are “made” during production. To better forecast its mechanical performance, Altair’s integrated simulation-driven design methodology begins with the injection moulding of the plastic component. Each component point’s anisotropic fiber orientation distribution is translated to the corresponding regions. However, the mechanical component uses a current injection moulding simulation as a base. Thus, a new description of the material incorporates the features typical of plastics into the mechanical analysis. Such as anisotropy, non-linearity, strain rate dependency, tension-compression asymmetry, failure performance, and temperature dependence.

Modeling of Materials Effectively

Including the micromechanics impacts of a fiber-reinforced material in a macroscopic FEA represents affordable numerical costs. However, Altair® Multiscale Designer® improves precision. In an integrated simulation method, the mechanical performance is anisotropic. The injection molding process causes this direction-dependent fiber dispersion. Moreover, the behavior of plastic reinforcement precisely predicts the combination of a 3D model of a single fiber. Also, the plasticity and damage laws of the fiber, plastic materials, and the statistical distribution of the fibers in the plastic. According to the preliminary analysis of the Plastic Injection moulding, the procedure identifies the required fiber orientation distribution of the entire component. Material models from Multiscale Designer apply to the implicit and explicit analysis.

.

Identifying Failure

After compressing or creating tension in plastic parts, they act substantially differently. Properties are nonlinear elastic, load-rate dependent, and heating and softening can result from cyclic loading. The same holds for loads that are parallel to and perpendicular to the direction of the fibers: plastic exhibits anisotropy failure. These effects necessitate a unique failure model that is plastic-specific. Another critical step in the design process is fatigue prediction for plastic components, which must consider the local component strength, multiaxiality, aging, condition, temperature, and load duration. S-Life Plastics by PART Engineering assesses plastic components’ short-term, long-term, and fatigue strength.

Continuous Design Process

For the entire process of creating injection-moulded components, Altair offers an open procedure. Results are highly accurate when material modeling is done using multiscale technology. Using Altair’s innovative licensing mechanism, all relevant simulation stages can be carried out utilizing Altair tools inside Altair OneTM. It is possible to integrate a proprietary structural analysis or injection moulding solution. The Altair Workflow supports your current workflow and effortlessly integrates with Moldflow, Moldex3D, Abaqus, LS-Dyna, or Ansys.